Have you ever wondered how to restore the natural beauty of your outdoor surfaces without resorting to tedious scrubbing or costly professional services? Well, I’m here to share a remarkable secret that could revolutionize your cleaning routine. Today, we delve into the transformative abilities of a remarkable tool that can eliminate unsightly blemishes, including the stubborn presence of corrosion on concrete.

Brace yourself for an eye-opening revelation that challenges conventional cleaning methods. Discover the potential of a versatile device that harnesses the forces of high pressure and cutting-edge technology. Prepare to witness the power of a cleaning solution that not only removes dirt and grime but has the potential to combat the detrimental effects of time and neglect.

Unleash the power of innovation and explore the possibilities that lie within the realm of this ingenious cleaning solution. With a combination of precision and efficiency, this revolutionary tool can penetrate even the toughest nooks and crannies to reveal a surface that gleams with renewed radiance. Say goodbye to the frustrating limitations of ordinary cleaning methods and embrace a new era of restoration.

Understanding Rust Formation on Concrete Surfaces

As I explore the phenomenon of rust formation on concrete surfaces, I am intrigued by the intricate processes involved in this natural occurrence. It is fascinating to delve into the science behind rust formation and gain a deeper understanding of how it affects concrete structures.

The Chemical Reactions Leading to Rust

Rust formation is a result of chemical reactions that occur when iron or steel, commonly found in concrete reinforcement bars or other metallic components, come into contact with moisture and oxygen. These reactions initiate the process of oxidation, leading to the formation of iron oxide, commonly known as rust. The presence of water acts as a catalyst for these reactions, accelerating the corrosion process.

In this mesmerizing dance of atoms and molecules, iron atoms lose electrons, leading to the formation of positively charged ions. These ions then combine with oxygen atoms in the presence of water molecules to form various types of iron oxide compounds, giving rise to the characteristic reddish-brown color of rust. These compounds weaken the structural integrity of concrete surfaces, posing a risk to their long-term stability and durability.

The Impact of Environmental Factors

Understanding the formation of rust on concrete surfaces requires acknowledging the role of environmental factors. Factors such as humidity, temperature fluctuations, and exposure to chemicals can significantly influence the rate at which rust forms. Higher levels of humidity create the perfect conditions for rust formation, as moisture is essential for the corrosion process to occur.

Furthermore, the presence of salts, acids, or certain pollutants in the environment can expedite rust formation. These substances can aid in the breakdown of the protective oxide layer on the metal surface, making it more susceptible to the corrosive effects of oxygen and moisture.

Conclusion:

The intricate interplay of chemical reactions and environmental factors contribute to the formation of rust on concrete surfaces. Understanding these processes enables us to develop effective strategies to mitigate rust formation and protect the longevity and structural integrity of concrete structures.

How Does a High-Pressure Jets Cleaner Work?

When it comes to cleaning stubborn dirt and grime, one of the most effective tools you can rely on is a high-pressure jets cleaner. This powerful equipment has the ability to remove tough stains and contaminants, leaving surfaces looking spotless and rejuvenated. In this section, I will explain how a high-pressure jets cleaner works and the science behind its cleaning prowess.

At its core, a high-pressure jets cleaner utilizes a motor-powered pump to create a strong jet of water that is expelled through a narrow nozzle. This forceful stream of water has high velocity and pressure, allowing it to dislodge and remove various types of dirt and debris from surfaces. The pressure generated by the cleaner can be adjusted depending on the cleaning task at hand.

When the trigger of the cleaner is pressed, water from a connected source flows into the motor-powered pump. The pump then pressurizes the water, forcing it through a small opening in the nozzle. As the water passes through the narrow opening, its velocity increases, resulting in a concentrated and powerful jet that can effectively remove dirt, grime, and even stains.

The high pressure of the water works by physically agitating the dirt and contaminants on the surface, dislodging them from their bonds and allowing them to be rinsed away. Additionally, the force of the water jet can also penetrate porous materials, such as concrete, effectively flushing out embedded dirt and debris that may be concealed within the surface.

Furthermore, the high-pressure jets cleaner can be used in combination with cleaning agents or detergents to enhance its effectiveness. These cleaning solutions can be mixed with the water before it enters the pump, allowing them to be sprayed onto the surface along with the pressurized water. The combination of high-pressure water and cleaning agents can provide an even more thorough and efficient cleaning process.

Overall, the working principle of a high-pressure jets cleaner lies in the powerful jet of pressurized water it creates. This jet, combined with the ability to adjust the pressure and use cleaning agents if needed, makes it a versatile tool for tackling various cleaning tasks, from removing dirt and grime on surfaces to restoring the appearance of outdoor spaces.

Potential Benefits of Utilizing High-Pressure Equipment for Eliminating Rust Spots

When it comes to restoring the pristine appearance of outdoor surfaces, sometimes rust stains can pose a real challenge. However, fear not, as I am here to shed light on the potential advantages of incorporating a high-pressure cleaning device into your rust removal strategy. By harnessing the power of concentrated water streams, you can potentially bid farewell to those pesky rust spots, restoring the elegance and cleanliness of your concrete surfaces.

1. Enhanced Efficiency: With the assistance of a high-pressure cleaning tool, you stand to benefit from increased efficiency in rust removal. The forceful streams of water can penetrate the porous surface of concrete, targeting the rust particles and loosening their hold. This accelerated process saves you time and effort compared to traditional cleaning methods, allowing you to tackle rust spots with greater ease.

2. Versatile Application: Another advantage of employing a high-pressure device is its versatility in dealing with various surfaces. Whether you are battling rust on driveways, patios, or walkways, these powerful tools can adapt to different textures and materials. This versatility ensures that you can effectively eliminate rust stains from not only concrete but also other hard surfaces, such as metal or wood, depending on the capabilities of the specific equipment.

- Preservation of Aesthetics: By effectively removing rust stains, high-pressure cleaning tools help preserve the aesthetics of your outdoor spaces. Rust spots can considerably detract from the overall appeal of your concrete surfaces and leave a negative impression. With the use of these equipment, you can restore the visual charm and attractiveness of these areas, making them more inviting for both residents and visitors alike.

- Prevention of Further Damage: Rust not only leaves unaesthetic marks, but it can also cause structural harm over time. By promptly removing rust with a high-pressure device, you can prevent it from spreading and causing further deterioration to your concrete surfaces. This proactive approach helps maintain the integrity and longevity of your outdoor spaces, saving you from potential extensive repairs in the future.

- Eco-Friendly Option: A notable advantage of utilizing high-pressure cleaning tools for rust removal is their eco-friendly nature. Unlike certain chemical-based products, these devices primarily rely on the force of water to eliminate rust, minimizing the use of harmful substances that may negatively impact the environment. Additionally, the water consumption can be regulated, enabling you to conserve water resources while effectively addressing rust issues.

In conclusion, the potential benefits of using high-pressure equipment for rust removal on concrete surfaces are numerous. From enhanced efficiency and versatile application to preservation of aesthetics and prevention of further damage, these tools offer a compelling solution to deal with rust spots effectively. Moreover, their eco-friendly nature makes them a responsible choice for those conscious of environmental impact. So why not consider incorporating a high-pressure cleaning device into your rust removal efforts and witness its effectiveness firsthand?

Things to Consider Before Using a High-Pressure Cleaning System on Concrete Surfaces

When it comes to cleaning concrete surfaces, using a high-pressure cleaning system can be a convenient option. However, before diving into the process, there are several important factors that need to be taken into consideration. As someone who has experience with pressure washing, I understand the potential risks and benefits involved. In this section, I will highlight some key factors to consider before utilizing a high-pressure cleaning system on concrete surfaces.

Surface Material and Condition:

Before applying high-pressure cleaning, it is crucial to assess the material and condition of the concrete surface. Different types of concrete may react differently to high-pressure washing, and certain surfaces may require special care due to their age or structural integrity. It is important to understand the specific characteristics of the surface being cleaned in order to determine the appropriate pressure levels and cleaning agents to use.

Environmental Factors:

Another essential factor to consider is the environment in which the concrete surface is located. Factors such as temperature, humidity, and the presence of nearby plants or delicate objects can influence the effectiveness and safety of pressure washing. It is important to account for these environmental factors to prevent any potential damage to surrounding areas or vegetation.

Preparation and Protection:

Proper preparation and protection are paramount when pressure washing. Before initiating the cleaning process, it is essential to remove any loose debris or obstructions from the concrete surface. Additionally, surrounding areas should be adequately protected with barriers or coverings to prevent any unintended spray or debris from causing damage or injury.

Safety Measures:

Working with high-pressure cleaning systems requires adherence to strict safety measures. Protective gear, such as gloves, goggles, and appropriate footwear, should be worn to avoid injuries from flying debris or accidental slips. Understanding how to use the equipment safely and effectively, such as maintaining a safe distance from the surface and avoiding direct contact with delicate areas, is crucial to prevent accidents or damage during the cleaning process.

Professional Expertise:

If you are unsure about any aspect of pressure washing concrete surfaces, it is always advisable to seek the assistance of a professional. Experienced professionals have the knowledge and expertise to assess the specific requirements of your concrete surface and can provide guidance on the most suitable pressure levels and cleaning techniques to use. Hiring a professional can help ensure a safe and effective cleaning process.

In conclusion, while pressure washing can be an efficient method for cleaning concrete surfaces, it is important to consider various factors before proceeding. Assessing the material and condition of the surface, accounting for environmental factors, implementing proper preparation and protection, prioritizing safety measures, and seeking professional expertise when needed are all crucial steps for achieving successful and damage-free results.

Steps to Eliminate Rust Stains on Concrete Using High-Pressure Equipment

When encountering stubborn rust stains on concrete surfaces, it can be frustrating to find an effective solution. However, I have discovered a reliable method to remove these unsightly stains using a powerful high-pressure cleaning device, which I am excited to share with you.

Preparation and Safety Measures

Before proceeding with the rust removal process, it is important to take necessary precautions to ensure safety. To begin, gather all the required protective gear such as gloves, safety goggles, and a dust mask to avoid any potential hazards.

Next, it is crucial to prepare the surrounding area by removing any objects or obstacles that may obstruct the cleaning process. This will allow for smooth and efficient stain removal.

Application of Rust Remover

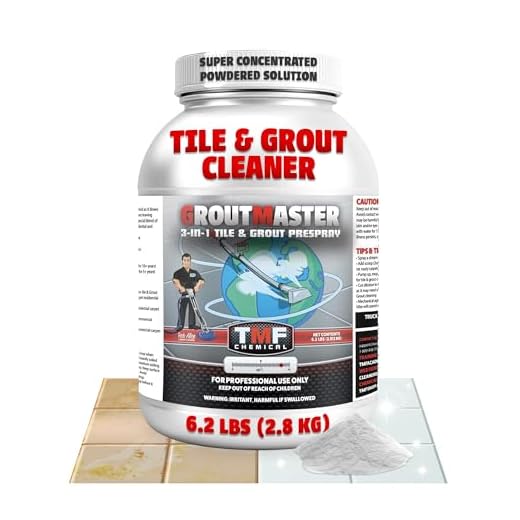

Once the preparation is complete, it is time to apply a suitable rust remover to the stained concrete surface. Choose a high-quality rust removal product that is specifically designed for use on concrete, as it will provide optimal results.

Using a scrub brush or a roller, evenly distribute the rust remover over the affected area. Ensure thorough coverage, allowing the product to penetrate the rust and break it down for easier removal.

Important Note: Follow the manufacturer’s instructions on the rust remover packaging for appropriate usage and safety guidelines.

High-Pressure Cleaning

After allowing the rust remover to sit on the concrete surface for the recommended period, it’s time to utilize the power of a high-pressure cleaning device.

With the rusted area in focus, adjust the pressure washer to a medium or high-pressure setting. These higher settings will help dislodge the rust particles from the concrete and restore its original appearance.

Tip: Begin cleaning from a lower pressure setting and gradually increase it to prevent damage to the concrete surface. Test a small, inconspicuous area first before proceeding with the entire stained section.

Move the pressure washer nozzle back and forth over the rusted area, applying consistent pressure to effectively remove the rust stains. Take care to keep the nozzle a suitable distance away from the concrete surface to avoid any accidental damage.

Continue the cleaning process until all rust stains have been completely eliminated. Once finished, thoroughly rinse the area with clean water to remove any remaining rust remover residue.

By diligently following these steps, you can achieve remarkable results and restore the beauty of your concrete surface without relying on professional assistance.

Exploring Alternative Approaches for Eliminating Rust on Concrete Surfaces

When it comes to dealing with rust on your concrete surfaces, there are various methods that can be considered apart from relying solely on the power of a pressure washer. In this section, I will share alternative approaches that have proven to be effective in removing rust, without the need for a pressure washer.

1. Scrubbing with a Wire Brush

One method that has proven to be quite successful for removing rust from concrete surfaces is scrubbing with a wire brush. By using a wire brush with firm bristles, you can manually loosen and remove rust deposits. This process may require some physical effort, but it can effectively eliminate rust from your concrete surfaces.

2. Applying Chemical Rust Converters

Another alternative method for removing rust from concrete surfaces is by utilizing chemical rust converters. These specialized products are designed to react with rust, transforming it into a stable compound that can be easily removed. Chemical rust converters usually come in liquid form and can be applied directly onto the rusted areas. Once the converter has dried, you can easily scrub away the transformed rust.

It is important to note that while these alternative methods can be effective in removing rust, they may not provide the same quick and efficient results as a pressure washer. Each method has its own advantages and limitations, so it is crucial to select an approach that suits your specific needs and the extent of rust damage on your concrete surfaces.

Remember, maintaining regular cleaning and preventive maintenance routines can help minimize the occurrence of rust on your concrete surfaces. By addressing rust issues promptly and effectively, you can ensure the longevity and aesthetic appeal of your concrete surfaces.

Disclaimer: The information provided in this article is based on personal experience and research. Please exercise caution and follow proper safety procedures when using alternative methods to remove rust from concrete surfaces.

FAQ:

Can a pressure washer remove rust stains from concrete?

Yes, a pressure washer can effectively remove rust stains from concrete surfaces. The high-pressure water stream helps to break up and wash away the rust particles, restoring the appearance of the concrete.

What pressure level is recommended to remove rust from concrete?

A pressure washer with a minimum pressure level of 3000 PSI (pounds per square inch) is recommended to effectively remove rust stains from concrete. Higher pressure settings can provide even better results but caution should be taken to avoid damaging the concrete surface.

Will a pressure washer alone completely remove rust from concrete?

While a pressure washer is an effective tool for removing rust stains from concrete, it may not completely eliminate all traces of rust. Depending on the severity and age of the rust stains, multiple rounds of pressure washing or additional rust removal methods like using rust converters or cleaners may be necessary for complete removal.