When it comes to giving new life to old surfaces, we often turn to powerful tools and techniques that can help us achieve remarkable results. One such technique is the combination of pressure washing and sandblasting, which allows us to remove layers of dirt, grime, and even stubborn coatings from various surfaces. This dynamic duo has gained popularity in the realms of cleaning and restoration due to its efficiency and versatility.

Enhancing the Power of Water

Pressure washing, using water under high pressure, is a well-known method for cleaning various surfaces. It can effectively remove dirt, stains, and even mildew with ease. However, when faced with tougher challenges such as removing thick layers of paint or deeply ingrained dirt, pressure washing alone may fall short.

This is where the power of sandblasting comes into play.

Unleashing the Abrasive Force

Sandblasting is a technique that utilizes abrasive materials, such as sand or garnet, to forcibly propel them onto a surface. The impact of these abrasive particles helps to remove unwanted layers, leaving behind a clean and smooth surface. Combining this abrasive force with the high-pressure water of a pressure washer creates a formidable duo capable of tackling even the most demanding cleaning and restoration tasks.

By harnessing the power of both techniques, we can achieve outstanding results that may be difficult to achieve using either method alone.

Versatility and Limitations

It is important to note that while this combination technique offers impressive cleaning and restoration capabilities, it may not be suitable for all surfaces. The force of the abrasive particles and high-pressure water can potentially damage delicate materials or substrates. Therefore, it is essential to assess the surface and determine its compatibility with these techniques before proceeding.

By understanding the strengths and limitations of pressure washing and sandblasting, we can utilize their combined power to effectively rejuvenate various surfaces and breathe new life into old and worn-out areas.

Is it possible to utilize a high-pressure water sprayer for abrasive cleaning?

When it comes to removing tough stains and grime from various surfaces, using a pressure washer can be an effective approach. However, have you ever wondered if a pressure washer could also be used for sandblasting?

As an enthusiast with a knack for DIY projects, I’ve always sought innovative methods to tackle cleaning tasks. Exploring whether a pressure washer can double as a sandblasting tool crossed my mind, leading me to conduct thorough research.

Although sandblasting typically involves the powerful force of sand particles propelled onto a surface, a pressure washer operates on a different principle. Instead of abrasive materials, it employs high-velocity water to dislodge dirt, mold, and other contaminants.

While a pressure washer’s ability to remove tough dirt and debris is indisputable, its suitability for sandblasting remains up for debate. Although some may claim success in adapting pressure washers for sandblasting purposes, it is essential to recognize the significant differences between the two techniques.

| Sandblasting | Pressure Washing |

|---|---|

| Utilizes abrasive media (e.g., sand, walnut shells) to clean surfaces | Relies on high-pressure water to remove dirt and grime |

| Effectively removes rust, paint, and other tough coatings | Ideal for general cleaning and surface preparation |

| Can sometimes cause surface damage if not used carefully | Gentler on surfaces, reducing the risk of damage |

Considering these variances, it is clear that while a pressure washer may deliver remarkable cleaning results, it may not suffice for the extensive abrasive cleaning provided by sandblasting equipment.

Ultimately, when confronted with a project requiring abrasive cleaning to achieve optimal results, investing in a dedicated sandblaster would be the most prudent choice. The cohesion of abrasive media with high-pressure air provides a unique advantage that a pressure washer cannot emulate, ensuring efficient and thorough cleaning.

Therefore, while a pressure washer remains an exceptional tool for general cleaning tasks, it falls short in replacing the specialized capabilities of a sandblaster. It is crucial to recognize and understand the specific requirements of each method to achieve the desired outcome for your cleaning endeavors.

Understanding the Difference: Pressure Washer vs. Sandblasting

When it comes to effectively cleaning surfaces, it is important to understand the difference between using a pressure washer and sandblasting. Each method offers its unique advantages and considerations, making it crucial to choose the right option based on your specific needs. In this section, I will compare pressure washing and sandblasting, highlighting their distinct features and applications.

Pressure Washer

A pressure washer, also known as a power washer, is a versatile cleaning tool that uses pressurized water to remove dirt, grime, and other unwanted substances from surfaces. With adjustable water pressure, it allows for efficient cleaning of various materials, including wood, concrete, metal, and more.

Pressure washing offers several benefits. Firstly, it provides a quick and convenient solution, as it can be easily used for both indoor and outdoor cleaning tasks. The high-pressure water stream can effectively remove stubborn stains and debris, making it ideal for surface preparation before painting or staining. Additionally, pressure washing is a safer alternative to using chemicals, reducing the risk of environmental contamination and potential harm to the user.

Sandblasting

Sandblasting, also referred to as abrasive blasting, involves using high-pressure air or water mixed with abrasive materials to remove paint, rust, or other coatings from surfaces. The abrasive material, such as sand, grit, or glass beads, is propelled at high speeds to effectively clean and prepare the surface for refinishing or painting.

Sandblasting offers unique advantages, especially when dealing with heavy-duty cleaning and restoration projects. It can remove thick layers of paint, rust, or even graffiti, making it suitable for surfaces that require deep cleaning or restoration. Sandblasting also allows for precise control over the amount of pressure and abrasive used, providing flexibility for tackling different materials and surface conditions.

| Pressure Washer | Sandblasting |

|---|---|

| Uses pressurized water to clean surfaces | Utilizes high-pressure air or water mixed with abrasive materials |

| Adjustable water pressure for various materials | Offers precise control over pressure and abrasive used |

| Quick and convenient solution for surface cleaning | Effective for heavy-duty cleaning and restoration projects |

| Safer alternative to using chemicals | Can remove thick layers of paint, rust, or coatings |

The Advantages and Disadvantages of Utilizing a Pressure Washer for Abrasive Cleaning

As an avid do-it-yourselfer, I have always been intrigued by the idea of using alternative methods for sandblasting, particularly with the use of a pressure washer. While traditional sandblasting equipment is effective, utilizing a pressure washer for this process brings about its own set of advantages and disadvantages. In this section, I will highlight these pros and cons to help you make an informed decision when considering this method.

Advantages:

1. Versatility: One of the significant advantages of utilizing a pressure washer for sandblasting is its versatility. The pressure washer can be easily adjusted to accommodate a wide range of surfaces and materials, allowing you to remove paint, rust, and grime from various objects such as cars, fences, or outdoor furniture.

2. Cost-effective: Compared to traditional sandblasting equipment, a pressure washer is more cost-effective. In most cases, purchasing or renting a pressure washer and the necessary accessories tends to be a more economical option, especially for occasional abrasive cleaning tasks.

3. Mobility: Pressure washers are typically portable, offering greater mobility when compared to larger sandblasting equipment. This makes them an ideal choice for smaller projects or tasks that require movement around different areas.

Though there are several advantages to using a pressure washer for sandblasting purposes, it is important to consider the drawbacks before proceeding.

Disadvantages:

1. Lower Abrasive Power: One of the main drawbacks of using a pressure washer for sandblasting is its lower abrasive power compared to specialized sandblasting equipment. While it can effectively remove surface contaminants, it may not be as suitable for more demanding or intricate cleaning tasks.

2. Limited Application: Pressure washers are primarily designed for cleaning purposes and may not be the best choice for certain materials or surfaces. They may not be suitable for traditional sandblasting tasks that require higher pressures and abrasive substances.

3. Safety Concerns: When utilizing a pressure washer for sandblasting, it is crucial to prioritize safety. The high-pressure water can cause potential injury if not handled properly, and proper protective gear such as goggles and gloves should always be worn.

Before embarking on any sandblasting project with a pressure washer, it is vital to carefully assess its advantages and disadvantages to determine whether it is the most appropriate method for your specific cleaning needs.

Choosing the Right Pressure Washer for Sandblasting

When it comes to sandblasting, finding the appropriate pressure washer is crucial. It is essential to select a pressure washer that is capable of effectively handling the job without causing any damage. In this section, I will share some insights on what type of pressure washer is best suited for sandblasting.

One important factor to consider is the pressure rating of the pressure washer. For sandblasting purposes, a pressure washer with a high PSI (pounds per square inch) rating is needed. This high pressure will ensure that the sand or abrasive material is propelled with enough force to remove unwanted coatings or debris from the surface being treated. Additionally, a pressure washer with a high GPM (gallons per minute) rating is also preferable as it will provide sufficient water flow to carry the sand or abrasive material effectively.

Another consideration is the type of nozzle that comes with the pressure washer. To achieve effective sandblasting, a nozzle with a narrow orifice size is typically used. This nozzle helps to create a concentrated stream of sand or abrasive material, allowing for precise and efficient cleaning. It is advisable to choose a pressure washer that offers different nozzle options, allowing you to adjust the orifice size depending on the specific sandblasting task at hand.

In addition to the pressure rating and nozzle type, the durability and construction of the pressure washer should also be taken into account. Sandblasting can be a demanding process that requires a pressure washer to withstand constant use and potential exposure to abrasive materials. Opting for a pressure washer with a sturdy frame, corrosion-resistant components, and a powerful engine can ensure its longevity and ability to handle sandblasting projects effectively.

In conclusion, selecting the right pressure washer for sandblasting involves considering factors such as pressure rating, nozzle type, durability, and construction. By choosing a pressure washer that meets these criteria, you can be confident in its ability to deliver optimal sandblasting results while protecting the surfaces you are working on.

The Necessary Equipment and Safety Precautions for Utilizing a High-Pressure Cleaning Device for Abrasive Blasting Purposes

When exploring the possibility of utilizing a high-pressure cleaning device to conduct abrasive blasting, it is of utmost importance to familiarize oneself with the essential equipment required and the safety measures that must be taken. This article aims to provide a comprehensive overview of the necessary tools and precautions to ensure a successful and safe sandblasting experience, without redundantly mentioning the terms “can,” “you,” “sandblast,” “with,” “pressure,” and “washer.”

Essential Equipment

Before attempting sandblasting with a high-pressure cleaning device, it is crucial to gather all the necessary equipment. The table below outlines the essential tools needed for a proficient sandblasting process.

| Equipment | Function |

|---|---|

| Abrasive media | Used to facilitate the cleaning process by removing unwanted materials from surfaces |

| Nozzle tips | Allows for controlled and focused release of abrasive particles |

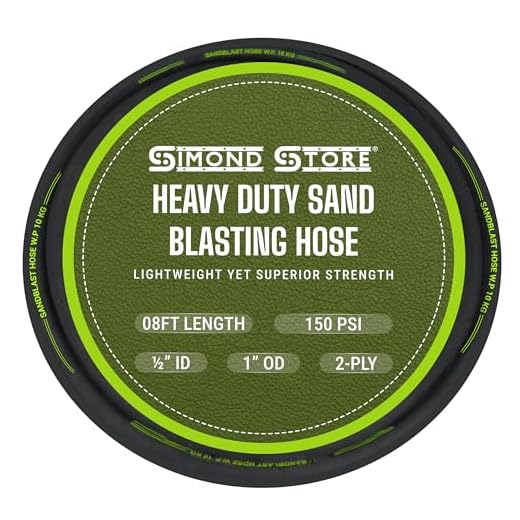

| Blast hose | Transfers the abrasive media from the storage container to the nozzle |

| Air compressor | Provides the necessary air pressure to propel the abrasive media |

| Blast pot | Stores the abrasive media and regulates its release |

| Protective gear | Includes goggles, gloves, and respiratory masks to ensure personal safety |

Safety Precautions

While engaging in sandblasting activities with a high-pressure cleaning device, it is vital to prioritize safety at all times. Adhering to the safety precautions below will minimize the risk of accidents and injuries:

- Always wear the appropriate personal protective equipment (PPE), such as a safety helmet, goggles, gloves, and respiratory mask, to shield yourself from potential hazards including flying debris and harmful dust particles.

- Work in a well-ventilated area or use an exhaust system to prevent the accumulation of hazardous dust and maintain air quality.

- Inspect all equipment before each use to ensure proper functionality and to identify any potential defects or damages.

- Never direct the high-pressure stream of abrasive particles towards another individual or yourself, as it can cause severe injuries.

- Securely anchor the sandblasting equipment to prevent unforeseen movement during operation.

- Establish a safety zone around the blasting area to restrict unauthorized access and ensure the protection of others.

- Adhere to recommended pressure levels and abrasive media quantities to prevent material damage and avoid potential equipment malfunctions.

- Have a reliable and appropriate fire suppression system readily available in case of emergencies.

- Properly dispose of used abrasive media and other waste materials in accordance with local regulations and guidelines.

By carefully following the necessary safety measures and utilizing the essential equipment, one can safely and effectively carry out sandblasting tasks with a high-pressure cleaning device, even if the terminology is not explicitly mentioned.

My Step-by-Step Guide to Effective Pressure Washer Sandblasting

Step 1: Preparation

Before starting the sandblasting process, it is crucial to prepare the necessary equipment and ensure the area is safe for the task at hand. Firstly, gather all the materials you’ll need: a pressure washer, an appropriate sandblasting attachment, a supply of sand or other blasting media, safety goggles, a dust mask, and protective clothing.

Next, carefully inspect the work area to identify any potential hazards and secure or remove them. By ensuring a clean and safe environment, you can effectively focus on the task and achieve optimal results without any unnecessary risks.

Step 2: Setting Up the Pressure Washer

The next step involves properly setting up your pressure washer for sandblasting. Start by attaching the sandblasting attachment to the wand of your pressure washer, making sure it is securely fastened. Consult the manufacturer’s instructions to ensure correct installation.

Once the attachment is in place, connect the pressure washer to a water source and make sure it is turned off. Ensure that all the connections are tight and that there are no leaks. Double-check the pressure settings to match the requirements of the sandblasting attachment.

Step 3: Filling and Operating the Sandblasting Attachment

With everything set up, it’s time to fill the sandblasting attachment with the blasting media. Choose an appropriate abrasive material for your project and carefully fill the attachment according to its capacity. Be cautious not to overfill, as it may affect performance.

Once the attachment is filled, put on your safety gear, including goggles and a dust mask, and switch on the pressure washer. Gradually increase the pressure and direct the sandblasting attachment towards the surface you want to clean or polish.

Step 4: Sandblasting Technique

Now that you have started sandblasting, it is essential to maintain the correct technique for optimal results. Keep the wand at an appropriate distance from the surface, usually around 8-12 inches, depending on the desired intensity and material being blasted.

Maintain a consistent and even sweeping motion across the surface, overlapping each pass slightly for uniform coverage. Avoid staying in one spot for too long, as it may cause unevenness or damage to the surface. Regularly check the progress and adjust the pressure and technique accordingly.

Step 5: Post-Sandblasting Cleanup

After completing the sandblasting process, it is important to clean up the working area thoroughly. Turn off the pressure washer and detach the sandblasting attachment, following the manufacturer’s instructions. Dispose of the blasting media responsibly and clean any remaining traces from the equipment.

Furthermore, inspect the surface you have sandblasted and remove any loose debris or residue. Depending on the project, you might need to perform additional steps such as rinsing, drying, or applying a protective coating to achieve the desired finish.

| Step | Description |

|---|---|

| Step 1 | Prepare the necessary equipment and ensure a safe work area. |

| Step 2 | Properly set up the pressure washer and attach the sandblasting attachment. |

| Step 3 | Fill the sandblasting attachment with the appropriate blasting media and operate the pressure washer. |

| Step 4 | Maintain the correct sandblasting technique, keeping a consistent distance and motion. |

| Step 5 | Complete the sandblasting process and perform post-cleanup tasks. |

Tips and Tricks for Achieving Successful Abrasive Blasting with a High-Pressure Water Jet

When it comes to the art of abrasive blasting using a high-pressure water jet, there are several tips and tricks that can vastly improve your results. As someone who has extensive experience in this field, I would like to share my insights and recommendations to help you achieve exceptional sandblasting outcomes without the need for specialized equipment.

- Choose the Right Abrasive Material: Selecting the appropriate abrasive material is crucial to ensure optimal results. Consider the surface you plan to blast and choose an abrasive medium that is compatible and effective for that particular application. Different materials, such as garnet, glass beads, or even baking soda, have varying hardness and impact to suit different surfaces.

- Prepare the Surface: Prior to sandblasting, it is essential to thoroughly clean and prepare the surface you intend to blast. Remove any loose debris, dirt, or contaminants that could hinder the effectiveness of the abrasive blasting process. This step sets the foundation for a successful sandblasting operation.

- Maintain Proper Nozzle Distance: Maintaining the correct distance between the nozzle and the surface being blasted is vital. Too much or too little distance can result in uneven blasting, causing inconsistencies and potential damage. Experiment with different distances to find the sweet spot that delivers the desired results for your specific project.

- Control Water Pressure and Flow: Utilizing a pressure washer with adjustable pressure and flow settings allows for better control during the sandblasting process. Adjusting these parameters to match the requirements of your project can improve the accuracy and efficiency of the sandblasting operation.

- Protect Yourself: Always prioritize safety when engaging in sandblasting activities. Wear appropriate personal protective equipment (PPE), such as safety goggles, gloves, long-sleeved clothing, and a respirator, to safeguard yourself from potential hazards. Sandblasting can generate airborne particles and debris, so taking necessary precautions is crucial.

- Practice Proper Technique: Mastering proper sandblasting technique takes practice and patience. Start with small, inconspicuous areas and gradually work your way up. Use smooth and even sweeping motions, ensuring consistent coverage without dwelling on any particular spot for too long. Practice makes perfect!

- Post-Blasting Cleanup: After completing the sandblasting process, it is vital to thoroughly clean the site and remove any residual abrasive material or debris. Proper cleanup helps maintain the integrity of the surrounding environment and ensures a smooth transition to subsequent steps, such as painting or surface treatment.

By following these tips and tricks, you can achieve remarkable sandblasting results using a pressure washer and create a surface that is ready for further treatment or coating. Remember, patience and attention to detail are essential for a successful sandblasting operation. Happy blasting!

Common Mistakes to Avoid When Using a Pressure Washer for Sandblasting

When it comes to utilizing a pressure washer for sandblasting tasks, it is crucial to be aware of some common errors that can occur. As I have gained experience in this field, I have discovered a few key mistakes that should be avoided in order to achieve optimal results.

1. Neglecting Safety Measures

One of the most important aspects of any sandblasting activity is safety. It is crucial to wear proper protective gear, including goggles, gloves, and a respirator, in order to protect yourself from harmful particles and substances. Failure to take adequate safety precautions can result in serious injuries or health hazards.

2. Using the Wrong Abrasive Material

Choosing the right abrasive material for sandblasting is essential for achieving the desired outcome. Some materials may be too harsh and can damage the surface being treated, while others may not provide enough abrasiveness to effectively remove the desired coatings or residues. It is important to research and select the appropriate abrasive material based on the surface and the desired outcome.

3. Applying Excessive Pressure

While pressure washers can provide significant force, it is essential to avoid using excessive pressure during sandblasting. Applying too much pressure can not only damage the surface being treated but also increase the risk of injury due to rebounding particles. It is crucial to find the right balance between pressure and abrasiveness to achieve optimal results.

4. Insufficient Distance and Movement

Another common mistake when sandblasting with a pressure washer is maintaining insufficient distance and movement. It is important to keep a consistent and appropriate distance from the surface being treated while continuously moving the nozzle. Failing to do so can result in uneven or incomplete removal, leading to unsatisfactory results.

5. Lack of Proper Equipment Maintenance

Maintaining the pressure washer and sandblasting equipment is crucial for achieving consistent and efficient results. Neglecting regular maintenance, such as cleaning the nozzles and filters, can lead to clogging or decreased performance. It is important to follow the manufacturer’s recommendations for maintenance and ensure that the equipment is properly cleaned and stored after each use.

In conclusion, by avoiding these common mistakes, one can enhance the effectiveness and safety of sandblasting using a pressure washer. Proper safety measures, selecting the appropriate abrasive material, applying the right pressure, maintaining proper distance and movement, as well as regular equipment maintenance, are key factors in achieving successful sandblasting results.

Exploring Alternative Solutions for Abrasive Cleaning When a Pressure Washer is Not Appropriate

When faced with a situation where a pressure washer is not a feasible option for sandblasting, it becomes necessary to explore alternative methods for achieving effective abrasive cleaning. In such cases, it is crucial to consider alternative tools, equipment, and techniques that can deliver similar results without the use of a pressure washer.

1. Handheld Sandblaster

One alternative method for sandblasting involves using a handheld sandblaster. This portable device allows for precise control and targeted cleaning in areas where a pressure washer may be impractical. By utilizing abrasive media such as sand or glass beads, a handheld sandblaster can effectively remove unwanted particles or coatings from surfaces.

2. Soda Blasting

Soda blasting is another effective alternative to pressure washer sandblasting. Instead of using traditional abrasive media, soda blasting incorporates baking soda as the blasting material. The soda particles are propelled at high speed, and upon impact, they disintegrate and remove the contaminants. Soda blasting is particularly useful for delicate surfaces or areas where water cannot be used.

| Pros | Cons |

|---|---|

| – Portable and easy to use | – Limited blasting capacity |

| – Precise and controlled cleaning | – Requires regular refilling of abrasive media |

| – Suitable for small-scale projects | – Not ideal for large or heavily adhered coatings |

| – Can be used in confined or hard-to-reach areas | – Additional protective measures may be required |

Exploring alternative methods for sandblasting becomes essential in situations where a pressure washer is not suitable. By considering options such as handheld sandblasters or soda blasting, you can find effective solutions to achieve the desired abrasive cleaning results.

Important Considerations for Choosing the Right Abrasive Material for Sandblasting

When it comes to sandblasting, selecting the proper abrasive material is crucial for achieving desired results. It is essential to consider various factors when choosing the right abrasive material, as different materials offer unique properties and benefits.

Abrasive Particle Size

One important consideration is the size of the abrasive particles. The particle size affects the aggressiveness of the blasting process and the level of surface roughness achieved. Fine particles are suitable for delicate surfaces or when a smoother finish is desired, while larger particles are more effective for removing heavy coatings or rust.

Abrasive Hardness

The hardness of the abrasive material plays a significant role in determining its effectiveness. Harder abrasives, such as aluminum oxide or garnet, are excellent for removing tough coatings or rust. Softer materials, like walnut shells or plastic beads, are ideal for more delicate surfaces, preventing damage while still achieving the desired cleaning effect.

Abrasive Material Type

There is a wide range of abrasive materials available for sandblasting, each with its own unique characteristics. Common options include aluminum oxide, silicon carbide, glass beads, steel grit, and crushed glass. Understanding the properties of each material is essential for selecting the most suitable one for your specific application.

- Aluminum oxide: Known for its high hardness and durability, making it ideal for heavy-duty applications.

- Silicon carbide: Offers excellent cutting ability and is commonly used for removing paint, rust, and scale.

- Glass beads: Provide a smooth and bright finish, often used for cleaning and polishing surfaces.

- Steel grit: Highly effective for removing tough coatings and preparing surfaces for new coatings.

- Crushed glass: Offers a sharp and aggressive profile, suitable for surface preparation and removing contaminants.

Consider the specific requirements of your project, such as the desired level of surface roughness, the type of coating or material to be removed, and the surface material being blasted. These factors will help you make an informed decision on the most suitable abrasive material for your sandblasting needs.